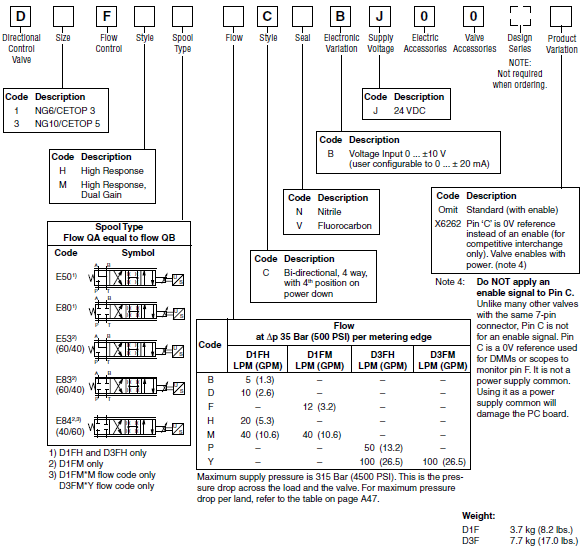

Series D*FH / D*FM High Response, Proportional Servovalve w/ On-Board Drive Amplifier

Key Features

- On-Board Electronic Drive Amplifier — The unit is shipped as a factory preset and tested unit. (No adjustment is necessary)

- High Frequency Response — The valve has a very high frequency response which is necessary for many closed loop applications.

- Four Position Spool Capability — The four position spool provides predictable flow in the event of a power failure to the drive electronics, within the limits of the power curve.

- 315 Bar Pressure Capability — The maximum operating pressure rating for the D*FH and D*FM is 315 Bar or 4500 PSI (Port P, A, B).

- Spool Position Feedback — The LVDT continuous feedback monitoring circuit provides low hysteresis and excellent repeatability.

- Drive Enable Feature — Output to the coil is shut down when the enable signal (10 to 30 VDC) is not present. The valve will then shift to the fourth position flow path selected by the user. (E50 or E80 spool)

- High Resolution Around Null — For precise control of critical position, force, or feed rates (D*FM Version only)

- Cylinder Ratio Adjust — To match following error on extend and retract. (D*FM Version only)

Series D*FH is a high response, proportional servovalve with an on-board drive amplifier. The D*FM is a high response, direct actuated servovalve with high resolution around low command inputs. The D*FM is designed for more precise control of position loops, force loops, and machine tool feed rates.

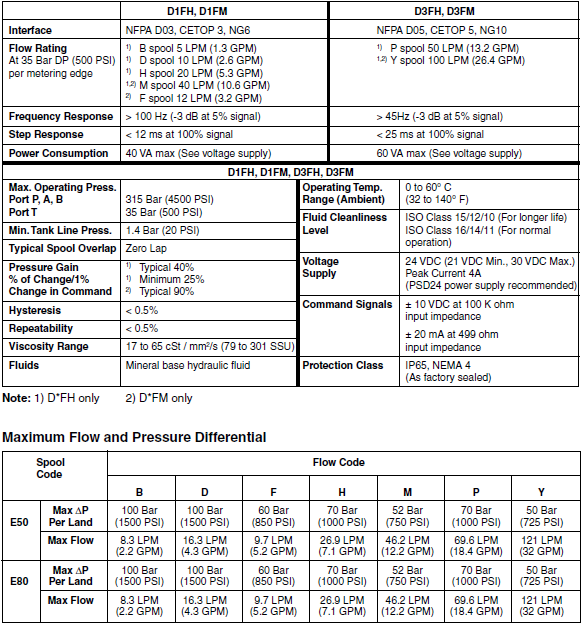

Series D*FH and D*FM incorporate the use of state-ofthe-art drive electronics with an LVDT for continuous monitoring of the spool position. Zero lap spools are standard for closed loop applications with two different ‘power down’ configurations. The valves feature frequency response levels greater than 100 Hz for D1FH and D1FM, and 45 Hz for D3FH and D3FM, along with low hysteresis and excellent repeatability.

Operation

Series D*FH

Series D*FH valve uses a precision lapped spool and sleeve configured with four control positions. During normal operation, the valve will shift from the center position to either side providing flow out the ‘A’ or ‘B’ port. When the drive amplifier is disabled by either removing the enable or loss of electrical power, the valve will shift through P?B in less than 10ms to a fourth position. The fourth position will block all four ports in one version. A second version that is available will block the ‘P’ port and allow the ‘A’ and ‘B’ ports to bleed to the ‘T’ (tank line). (Refer to the “Flow With No Enable” in Troubleshooting section)

Series D*FM

The high resolution Series D*FM adds hydraulic and electronic control compensation to the standard D*FH valve. This feature enhances the tuning and accuracy of systems utilizing high resolution feedback transducers and control compensation available in high performance motion controllers. The D*FM valve uses a precision lapped spool and sleeve configured with four control positions. The fourth position (disabled) is available in an all ports blocked configuration or ‘A’ and ‘B’ ports bleed to tank configuration.