TB Series Modular Terminal Blocks

Key Features

Blocks—Design Features

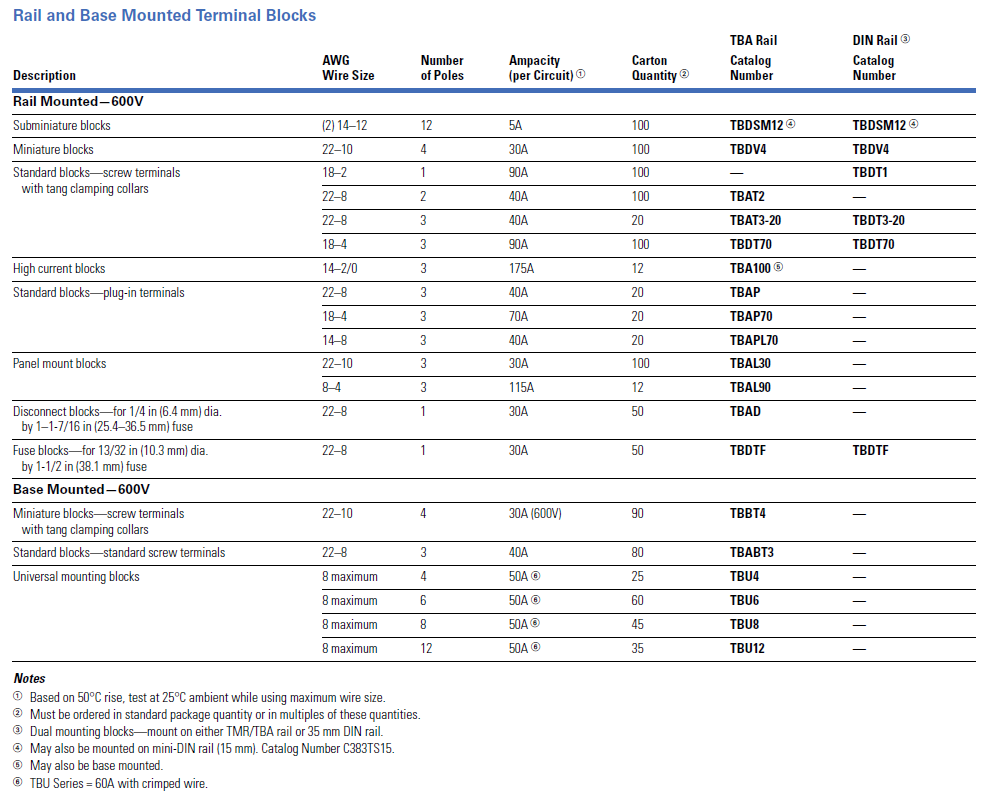

- Compact design permits mounting 48–600V or 90–300V terminals per foot

- Fully shielded construction, 600V spacings

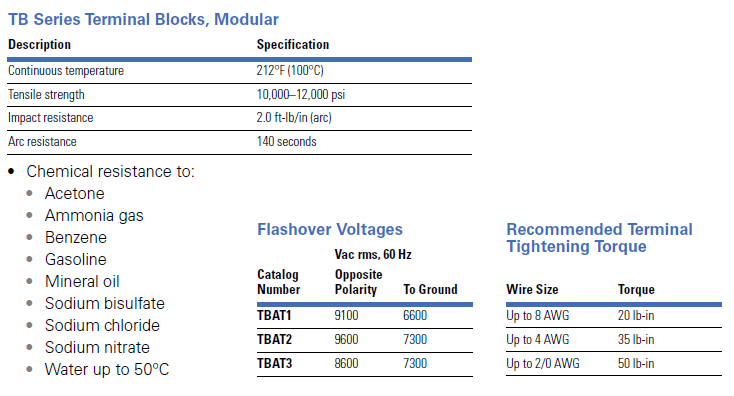

- Nylon construction provides anti-tracking and impact resistance

- TBA types are available in rail mounted, base mounted and power distribution types

- Terminal blocks easily snap on or off mounting rails; not necessary to disturb adjacent units

- No end pieces or backing plates are needed when rail mounting

- A 12 circuit subminiature blocks, rated 20A at 300V, is available for “high density” applications

- Popular blocks are also available in dual mount for use with standard TBA or 35 mm DIN rails

Terminals—Design Features

- Insulated walls of lug guide wire into lug

- Blocks are shipped with clamping screw backed out

- Constant locking torque keeps terminal screws in position

- Terminal screws are captive; cannot be lost in shipment or handling

- Hardened stainless steel clamping collar eliminates stripped threads

- Large opening in clamping collar accommodates oversized conductors; smallest collar will accept three 14 AWG stranded conductors

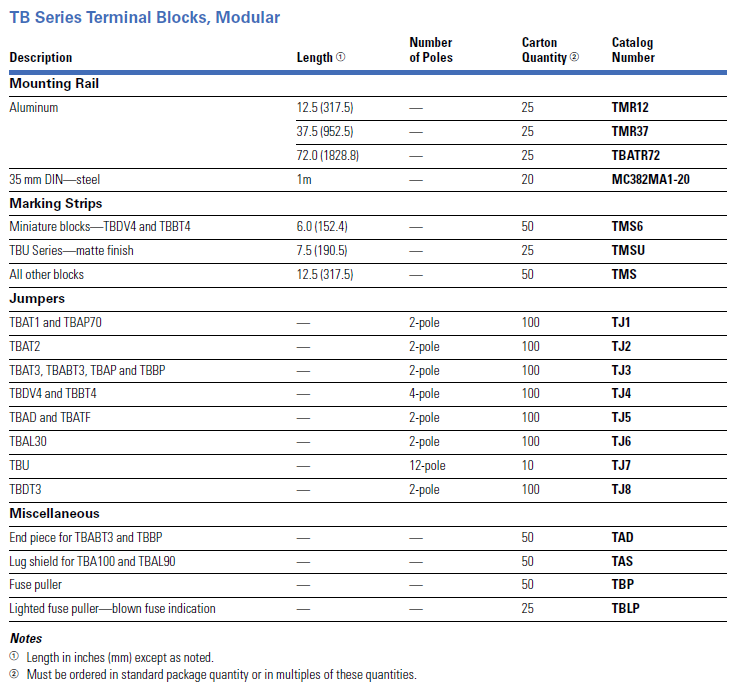

TBA and TBD modular terminal blocks are designed to conserve space, while allowing maximum flexibility and ease of installation. Available as one-, two- and three-pole circuits, simple and uniform installation is possible because their design is based on 5/8 in (15.9 mm) modules. Standard blocks are white nylon.

Breathing Action Clamping Collar

The unique design of the clamping collar permits the collar to breathe as the wire expands and contracts, maintaining a constant and permanent clamping pressure. This eliminates loose connections resulting from the gradual flattening of conductors and joint deterioration caused by heating and cooling cycles.

Standards and Certifications

- UL recognized: File No. E56797

- CE approved