Parker Industrial Hose

4500 Series Bottom Loading Hose

4500 Series Bottom Loading Hose

Parker composite petrochemical hose is economical, flexible, light weight, durable and resistant to abrasion, kinking and vibration. Parker composite hose assembly systems - using a new generation of hose constructions, innovative dry seal coupling technology and parker crimping equipment - save time and expense due to quick fabrication, easy installation and superior long-lasting performance. Assemblies manufactured per customer requirement; hydrostatically tested to 150% of the rated working pressure.

Applications

- Hose loading arms in bottom loading applications at bulk distributing and refining facilities

- NOTE: Not for dry material service.

Model Series

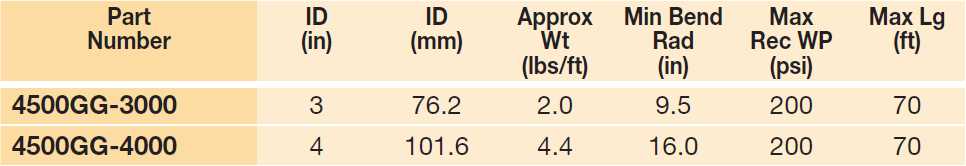

- 4500GG-3000, 4500GG-4000

| Inner Wire: | Galvanized steel (G) |

| Inner Liner: | Polypropylene fabric |

| Hose Wall: | Multiple layers of fabric/film/tubes |

| Cover: | Blue PVC coated polyester |

| Outer Wire: | Galvanized steel (G) |

| Temp. Range: | -40°F to +212°F (-40°C to +100°C) |

| Brand Method: | Black text on gold stripe |

| Brand Example: | PARKER SERIES 4500 BOTTOM LOADING HOSE 200 PSI MAX WP MADE IN USA |

| Design Factor: | 4:1 |

| Industry Standards: | None applicable |

| Vacuum: | Full |

| Compare to: | Peraflex BL-GGP Bottom Loading; Tift 901/401 Bottom Loading; Uni-Chem Uni-BL; Wilcox 4124SS/4121SG |

| Standard Wire: | G (Galvanized) inner and outer |

| Coupling Rec: | Permanently attached one-piece TTMA (Truck Trailer Manufacturers Association) flanges. Refer to page 387 for standard factory coupling options. |

| Assemblies: | Per customer requirement; hydrostatically tested to 150% of the rated working pressure. Contact Parker. |

Catalogs

156.4 kB