G Series TPE Parprene™ Tubing

Key Features

- Excellent flexural fatigue resistance

- Ozone and UV light resistant

- Temperatures from (-75°F to 275°F)

- Abrasion resistant

- Resistant to environmental stress cracking

- Lot-to-lot traceability

- Chemically compatible with common sanitizers and cleaners

- Extensive range of compatible Parker fittings and couplers

Applications

- Wastewater Sampling

- Cable Insulation

- Caustic Dispensing

- Ink and toner feed lines

- Chemical Transfer

Parprene™ TPE Tubing-Series G, the newest product from Parker Hannifin's Parflex® Division, is a thermoplastic elastomer tube formulated to withstand the rigors of peristaltic pump applications. Parprene tubing offers extreme flexibility, low permeation, abrasion resistance and resistance to stress cracking.

Parprene™ TPE Tubing-Series G, the newest product from Parker Hannifin's Parflex® Division, is a thermoplastic elastomer tube formulated to withstand the rigors of peristaltic pump applications. Parprene tubing offers extreme flexibility, low permeation, abrasion resistance and resistance to stress cracking.

Parprene™ Tubing provides a long service life and lot-to-lot traceability is available on every box shipped, allowing complete traceability from the resin to the finished product.

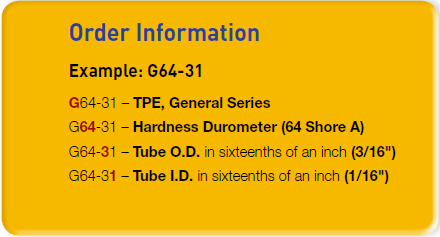

Coupled with Parker barb fittings, Parprene™ Tubing creates a fatigue resistant assembly for fluid and gas applications. When requesting information, please let your representative know you are looking for Parprene™ Series G: Industrial.

Notes

- TPE is a thermoplastic elastomer formulated to withstand the rigors of peristaltic pump applications and yet, be safe enough for food and beverage applications.

- Suggested operating temperature range for service at rated pressures with compatible fluids is -75°F to +275°F (-59°C to 135°C)

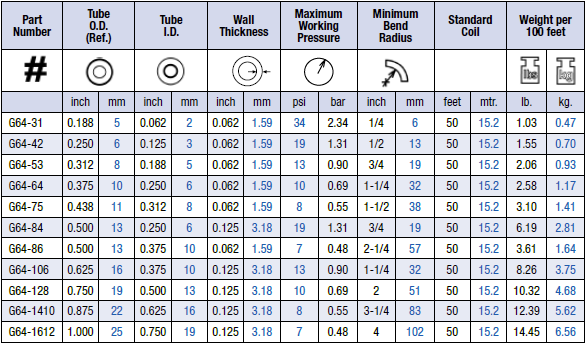

- Packaged 50 foot coils - sealed clear polyethylene bag, barcoded, 1 per box for lot traceability

- Special lengths available, contact Parflex division