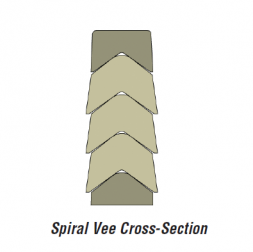

Symmetrical Seal Spiral Vee Profile

Cut to Size Chevron Packing

Standard Materials:

- To ensure the compatibility with the many organic (petroleum-based) and synthetic fluids used in hyrdaulic applications, Parker offers its Spiral Vee Ring products in a wide range of compounds, including Butyl, FKM, HSN, Nitrile, and a variety of fabric/rubber combinations. Shims and adapters are availble in bronze, FKM, Nylon, phenolic, P.E.E.K. and a variety of fabric/rubber combinations.

Availability:

- Cross section ranges from 0.375" to 1.0"; 49' to 62 feet/spiral; with mandrel ID's from 6" to 20"

Parker Spiral Vee Rings are precision-formed rubber and combination rubber/fabric sealing products designed to protect equipment from leakages and costly down time. These rings are manufactured using a single-step process that molds the entire spiral length of the product at one time. This process dramatically reduces scrap, and eliminates the potential for variations in hardness caused by over or under-curing at an overlap area. Once cured, the spiral length is pre-formed onto mandrels of varying diameters. Parker spiral vee rings are designed to work in combination with adapters and shims. Adapters, which typically consist of rubber or plastic rings, are fitted to the top and/or bottom of the vee ring stack to enhance sealing performance and prohibit extrusion. Rectangular cross-section discs, or “shims,” are used to adjust the height of the vee ring stack set to pre-existing groove depths.